helical end mills feeds and speeds

To learn more about how to use our charts visit our Speeds Feeds Guide. Tipped End Mill 13642 48-005 na na 1 na na na 12 Straight V Carbide Tipped End Mill 13564 48-072 na na 2 na na na 14 Upcut Carbide End.

End Mill Helix Angle Selection Blogs Www Cnctimes Com

- With or Without coolant.

. Using current input - Data results are for. For AD equal and above Tool Dia. - Dimension tolerance.

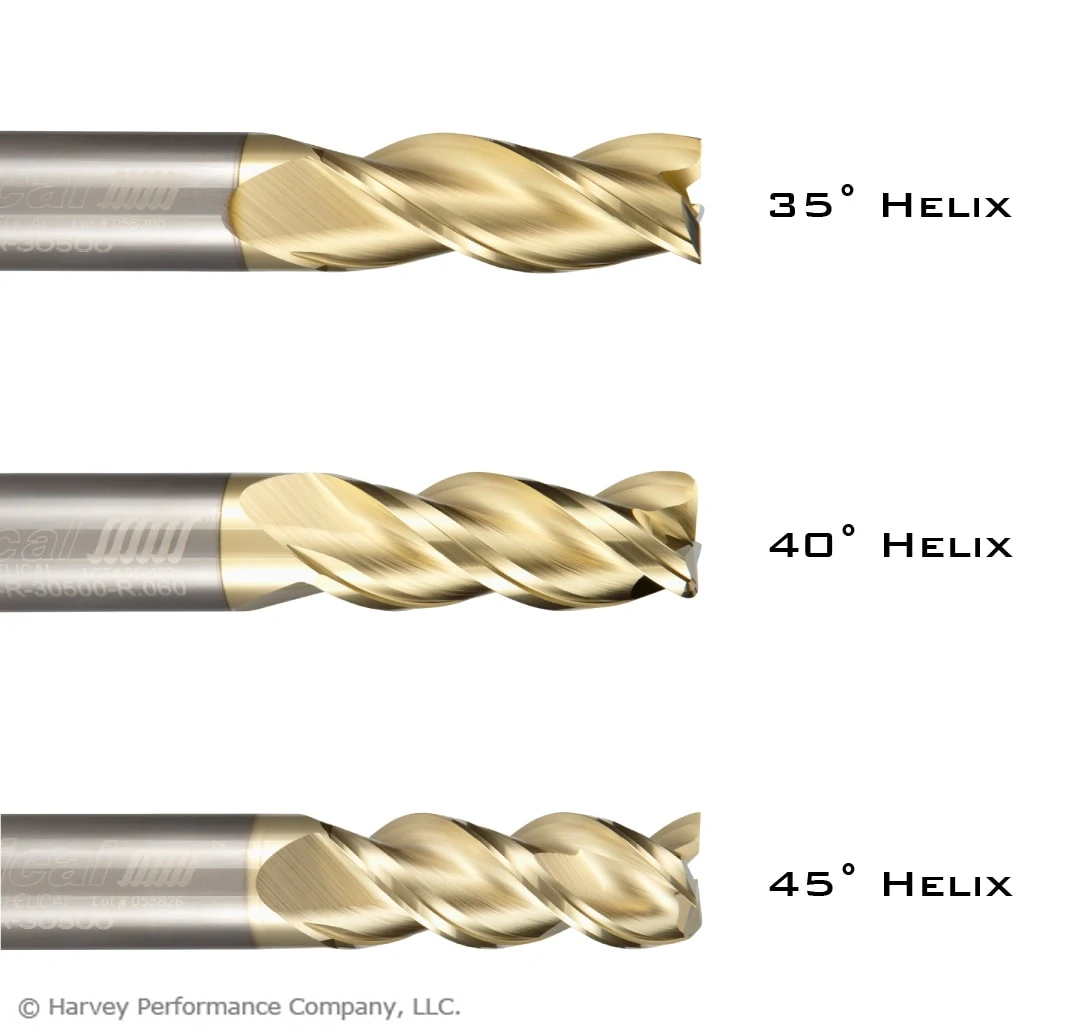

SFM 08 Lowest Range Value. 45 Degree Variable Helix Primarily for high-speed machining of aluminum plastics and other non-ferrous materials including brass and bronze alloys. If you think about my hole mentioned in the first post a 375 cutter creating a 75 hole the ramp angle is actually going to be 90 degrees on the inside.

- 00 -70 7 Helix. All posted parameters are suggested starting values that may be increased given optimal setup conditions. PCD End Mill is a superior cutting tools capable of side cutting and center cutting with high feeds and speeds.

Feed at Suggested Value. Determine the spindle speed RPM and feed rate IPM for a milling operation as well as the cut time for a given cut length. Calculations use the desired tool diameter number of teeth cutting speed and cutting feed which should be.

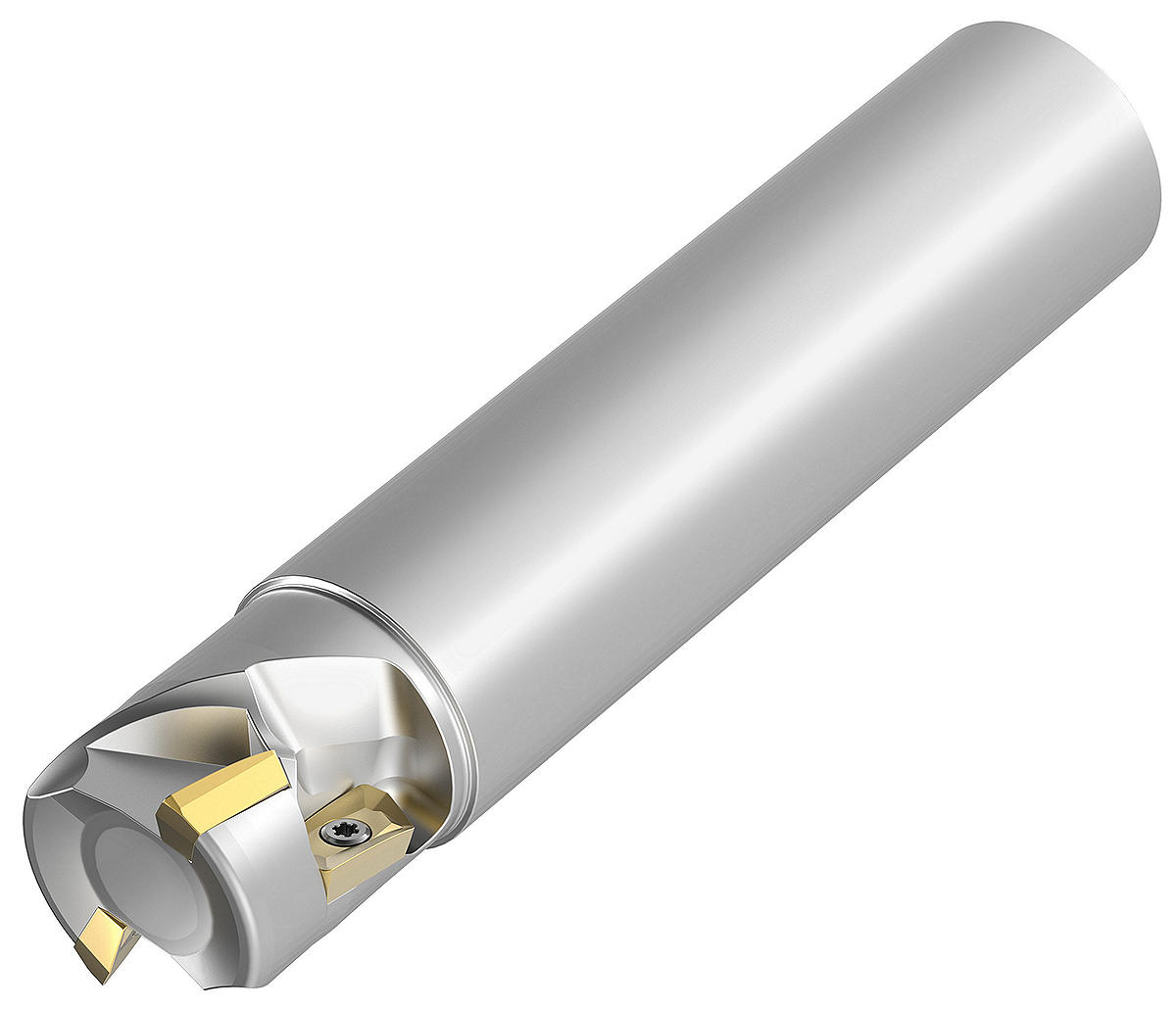

End Mill Speeds And Feeds - TiN Coated Carbide. Cm Number of circularhelical tool path revolutions. Helicals fully stocked offering of High Feed End Mills is designed for outstanding performance and maximum feed rates in aluminum and non-ferrous materials.

Helical makes the best endmills considering price and what they do for you. 3 flute metric end mill for aluminum offered in uncoated styles or with Zplus coating which smooths the end mills flute v. Ad Discover Products by Brand Type Size.

Then decrease speed by 10. Combination Feed HEM - 5 Flute - Chipbreaker Rougher - Variable Pitch This offering of High Feed End Mills used for both high feed and High Efficiency Milling HEM applications features tooling with offset chipbreaker geometry for optimal chip evacuation minimized harmonics and reduced tool pressure. Aph Z-axis depth for one helical revolution circular 0.

Nowhere in the line do you program a ramp angle however you do enter a z movement. Feed should be 05 X Suggested Value. 3 Flute Corner Radius - 40 Helix Variable Pitch Unique 3 teeth-to-center end geometry on this 40 variable pitch end mill helps with swift tool entry in.

Since not every company has the RPM or need for high Metal Removal Rates MRR. - Can also be made with CBN Flutes CBN End Mills. SFM and Feed For AD between 025 to 05 of Tool Dia.

SFM 08 X Highest Speed Range. Enter axial depth of cut if needed at start - before helical move. Speeds Feeds Library.

Ships and Delivers Fast. SMM SFM X 3048. Combination Feed HEM - 5 Flute - Chipbreaker Rougher - Variable Pitch This offering of High Feed End Mills used for both high feed and High Efficiency Milling HEM applications features tooling with offset chipbreaker geometry for optimal chip evacuation minimized harmonics and reduced tool pressure.

A feature on a variety of high. Mild - 1018 2-3 Carbon 420 0006016mm 0011028mm 0017043mm 002051mm. Had my Ingersoll rep out here one day Ingersoll supplies almost all my carbide insert tooling and I asked him about the Ingersoll carbide end mills.

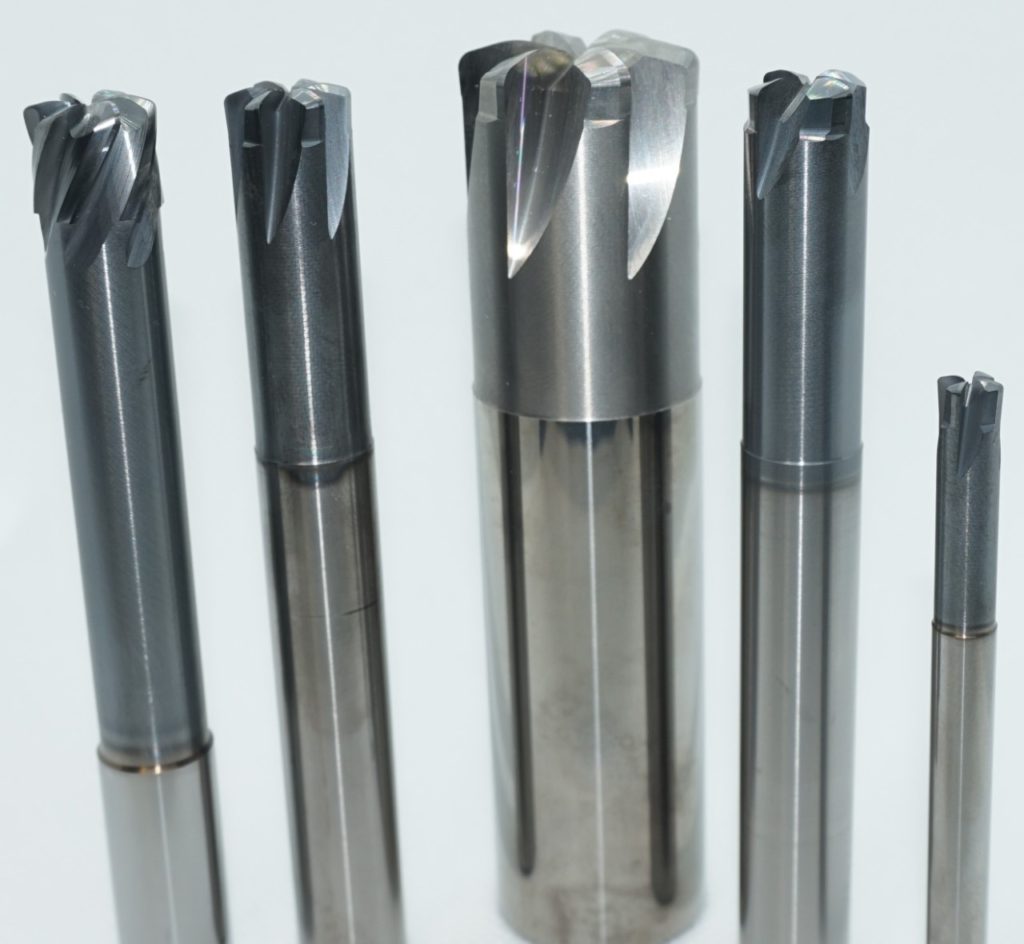

Helical PCD End Mills - Can be made with 2 or 3 or 4 Flutes. Ad Inch and Metric Mills - Single or Double End Roughing Mini Long Ball End. Hanita used to be my favorite but Helical displaced them a few years back.

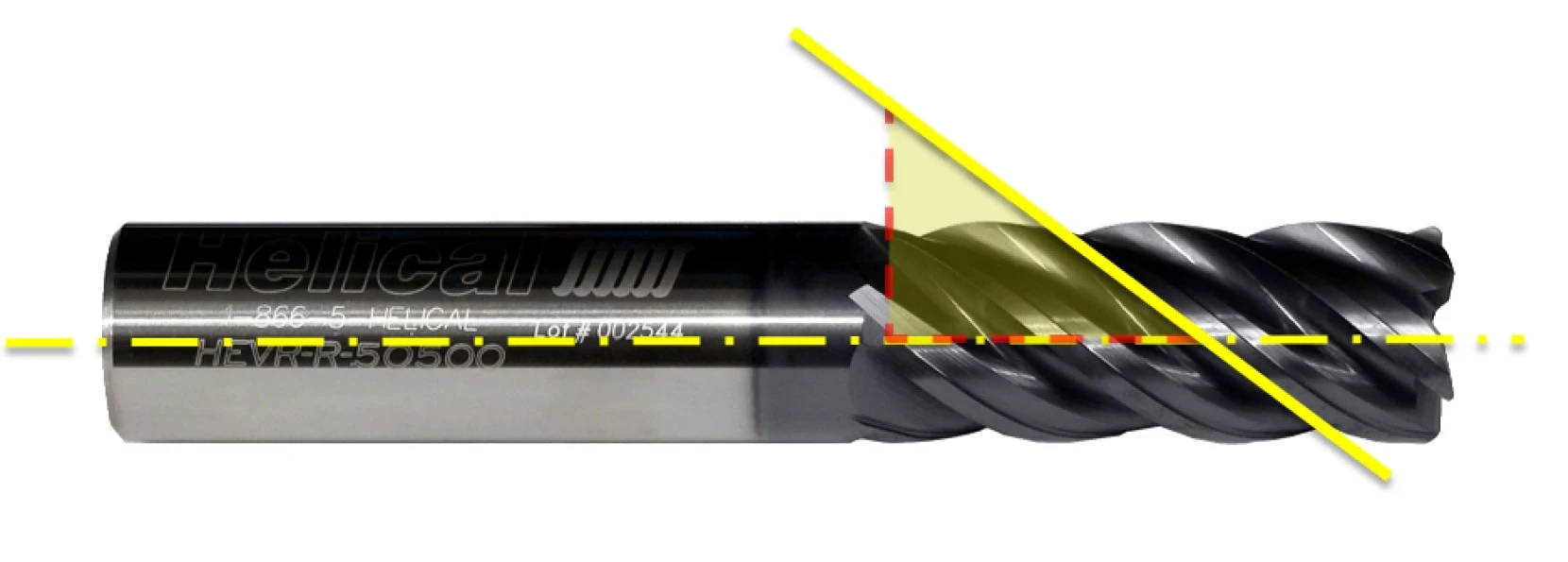

Determining the right speeds and feeds for your tool and operation can be a complicated process but understanding the ideal speed RPM is necessary before you start running your machine to ensure proper tool life. RPM 12 Surface Speed PI Tool Diameter revsmin Feed Rate RPM Chip Load Number of Teeth Flutes inmin Where PI is the constant 3141592654. MAP is our go-to solution for High Efficiency Milling and has exponentially decreased our run times as well as increased our tooling life.

Our Viper DVH series end mills are for both roughing and finishing. Feeds - IPT inchestooth and MMPT mmtooth Material. Its reduced neck geometry provides maximum strength in long reach and deep pocketing applications while its end profile provides optimal tool engagement and reduced cutting forces.

Below you will find downloadable and printer-friendly Speeds Feeds for each one of our products. Increase the cutting speed feed rate until the quality of the parts finish starts to decrease or the part is starting to move from hold downs. Machining Advisor Pro paired with Helical End Mills is the Holy Grail of End Mill Performance.

Viper DVH Speeds Feeds. Speeds and feeds speeds and feeds for boring tools material plastic magnesium aluminum copper brass bronze cast iron steel titanium stainless nickel monel inconel waspaloy hastelloy type teflon nylon phenolic glass filled azamezzehk 2021 thru 6061 101-707 834-978 gray ductile malleable 1005-1029 1030-1055 1060-1095 10l45-10l50 12l13-12l15. What Im attempting to do is optimize my feeds and speeds to gain better control of accuracy and finish.

The Speeds and Feeds Calculator uses the following formulas. Running a tool too fast can cause suboptimal chip size or even catastrophic tool failure. Ad High Helix for Improved Shearing Action Finish in Aluminum.

Milling operations remove material by feeding a workpiece into a rotating cutting tool with sharp teeth such as an end mill or face mill.

Specification Variable Helix End Mill

End Mills With Diameter 20 Mm For Milling Experiments A End Mill With Download Scientific Diagram

High Helix Carbide End Mill At Rs 3000 Unit Solid Carbide End Mills Id 20478637012

Helix Diameter Archives Harvey Performance Company

4 6 Flute High Feed End Mills Epic Tool

Mill 1 10 Helical Indexable Helical End Mills

End Mill An Overview Sciencedirect Topics

End Mill Tool With High And Low Helical Flutes And Related Method For Rough Cutting And Finishing A Workpiece Destiny Tool